Overview

Have you ever seen people riding around on those crazy electric longboards/ skateboards? They're always weaving in and out of traffic on sidewalks, streets, even dirt! Yeah, that's me, I am one of those people. Now think: have you ever seen anyone riding their boards in the rain? Probably not.

I had this problem as well. I couldn't ride my longboard in the rain because the wheels would kick up too much water and soak my pants. To resolve this issue I created custom fenders for my longboard via Solidworks and the the Ender V3 3D printer.

Tagline

Sorry!

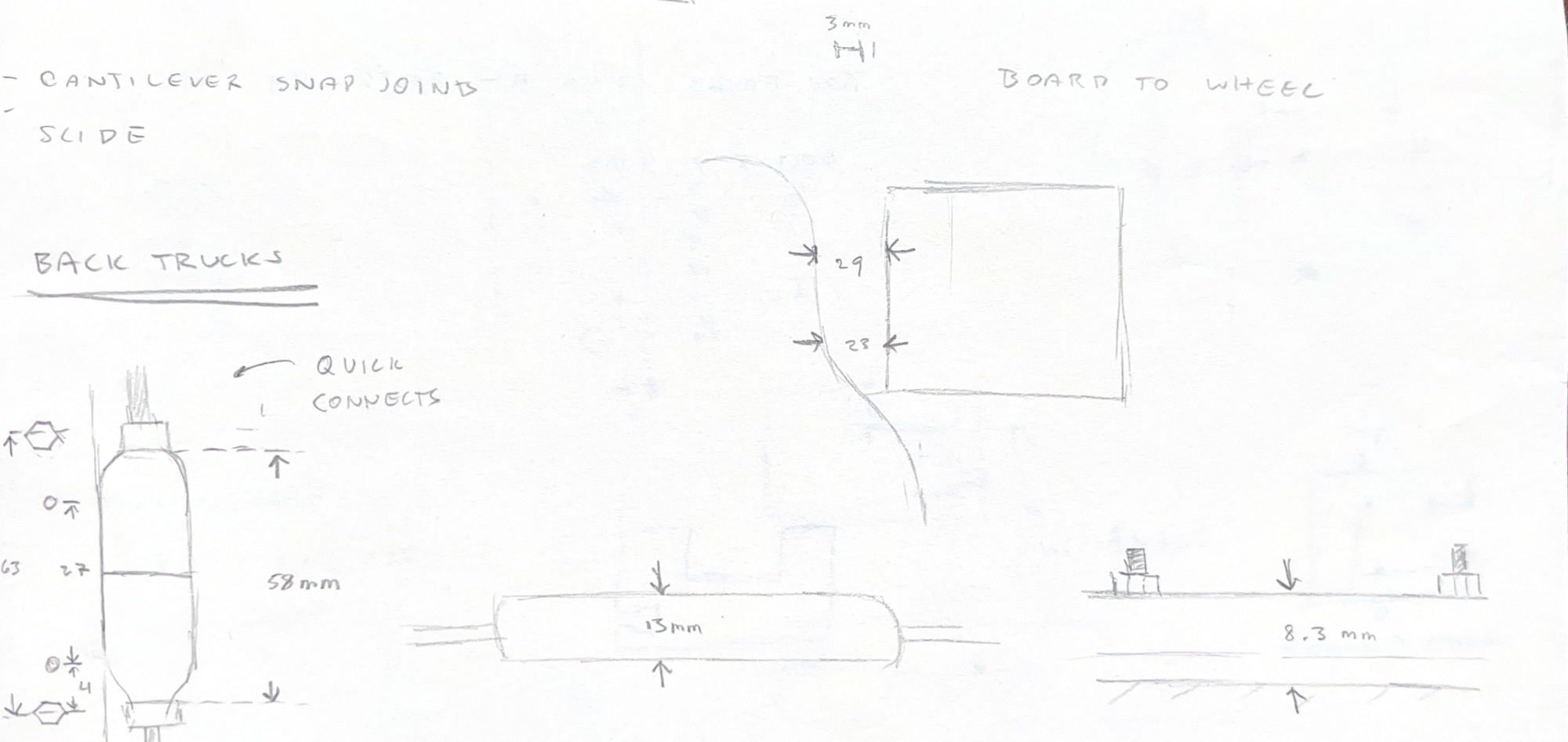

Originally, I had measured the dimensions of the trucks of my longboard, BUT Onedrive deleted all my notes and models so I have photos of the print instead

Challenges

This was a challenging project in the sense that I had limited access to quality of the print, durability of the print, the mounting method of the fenders onto the board, and accommodating the movement of the trucks and board when turning.

Mounting Method

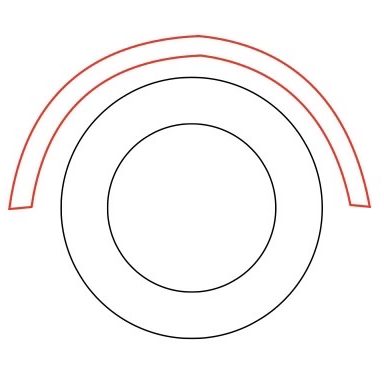

First challenge of this project was finding a way to mount the fender onto the board itself. As you can see when the board turns, the amount of space between the top of the wheel and the deck of the board increases and decreases. The wheels also get closer and farter from the deck depending on what direction you are turning.

To address this issue, I decided to mount the fenders directly onto the trucks, including a height just tall enough to clear the wheels, and just short enough not to hit the deck of the board.

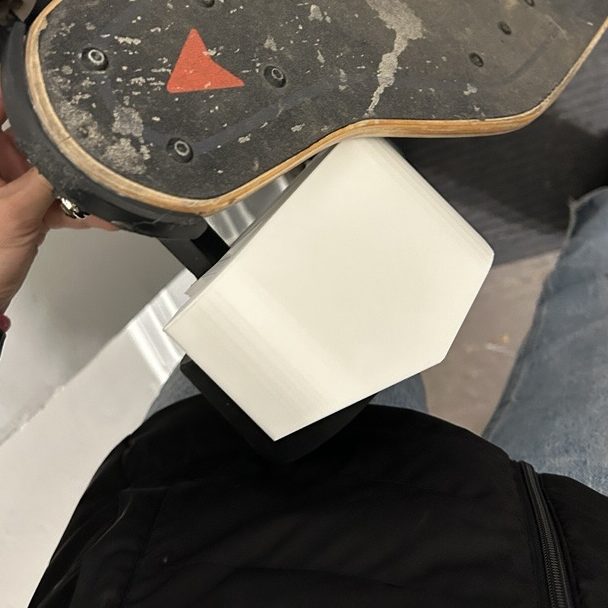

First attempt at fenders!

The first attempt at making these fenders was a step in the right direction, but not enough to get to the finish line.

The height of the fender is too large, causing the board to hit during turns. It's also too long. It covers the entirety of the wheel, but ran into the back curve of the deck .

The original mounting method included the print essentially hugging the truck, but this was too flimsy, and caused the fenders to fall off easily.

After a few test runs and assessments it was onto the next!

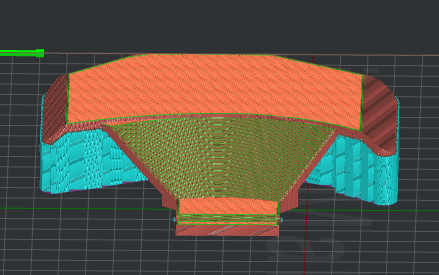

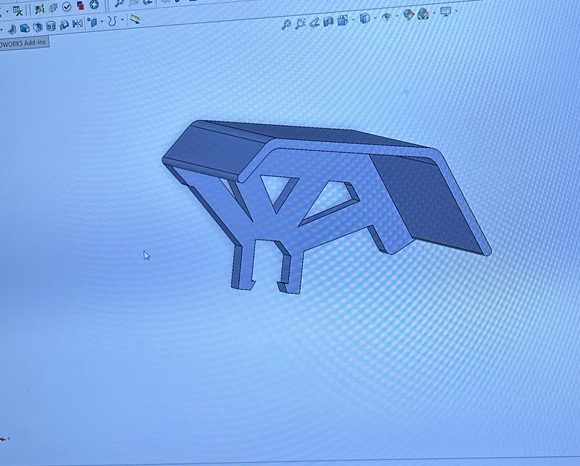

Second Design Attempt

The second design attempt to create these fenders included a much much smaller profile. The fender was slightly more rigid, and essentially hugged the wheel more to accommodate the small amount of space allowed for turning.

You can see the original mounting method still on this design. The shape of the truck cut out with hooks to lock the fender onto the board. (This design didnt work, but this picture had a better view of the mounting method itself.)

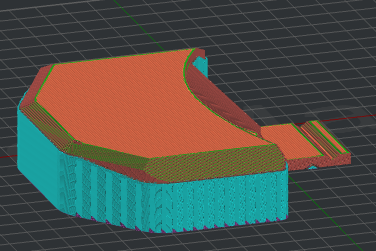

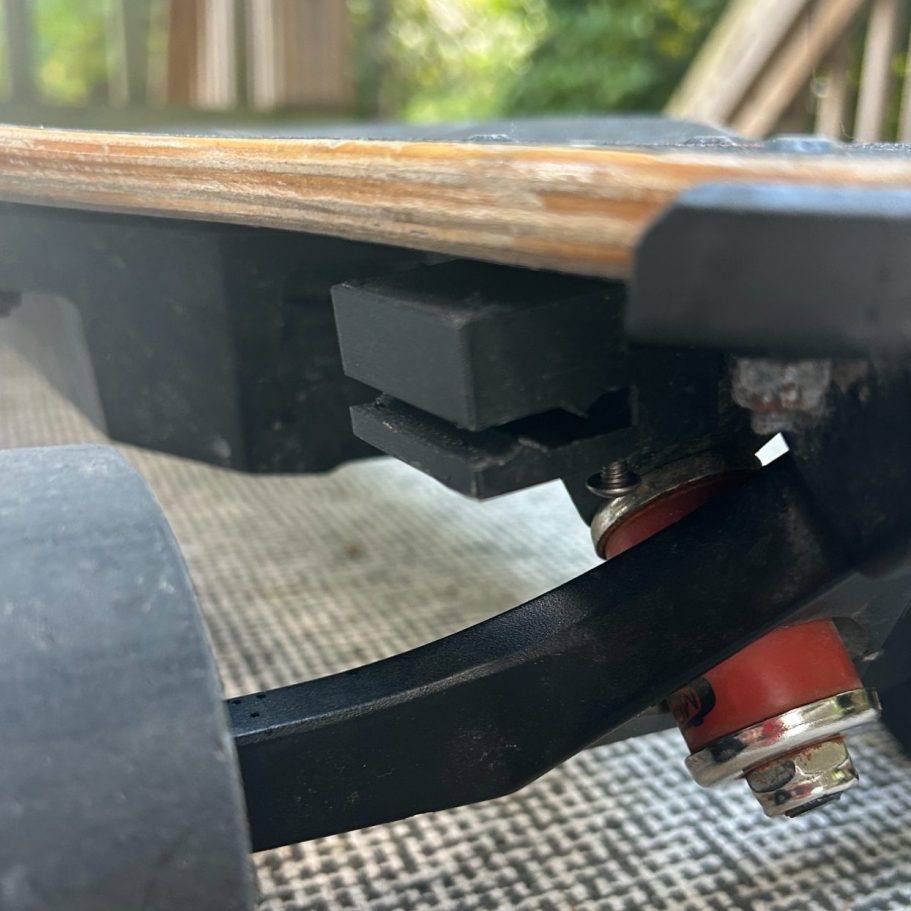

Most Recent Design

This is my third and most recent design attempt.

One thing I had in mind when thinking about these fenders, is that I wanted to be able to take them on and off. Because the previous snap design was not sturdy enough, I went ahead and utilized the natural hardware on the board to install a secondary mounting piece for my fenders. These mounting elements stay on the board at all times out of the way, and allow for the addition of the fenders when needed!

Future Plans

Though the current design is checking off the boxes, I feel it could still be improved. My plans for these fenders is to continue to slim down the design as much as possible. To do this I plan to implement a rounded design instead of a geometric shape with sharp corners and a flat top. This design will essentially hug the wheel closely becoming something of an extension of the wheel itself.